Intro: Project Goals & Objectives, Overview

of Work, Advancing into the Past, Tools

of the Trade,

Participating.

Soldier Hut Rehabilitation:

Overview of Initial Work

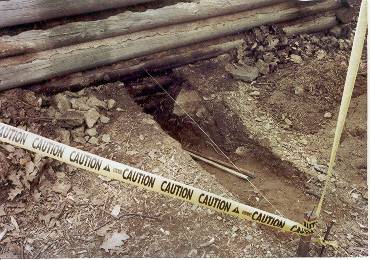

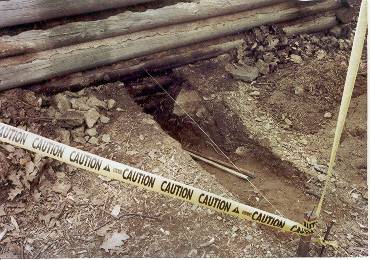

One of the first steps was to put a halt on water damage. A major

part of this was to dig out the back logs of the huts which had become

buried in soil over the course of 30 plus years. The grade was returned

to its 1966 profile and stabilization efforts have begun.

Trench dug by NPS Archaeologist revealing the depth of

fill from 30 years of erosion and composting leaves that were not removed

regularly. Morristown maintanence staff completed the regrading with

some assistance from volunteers. The bare soil was then covered with

biodegradeable erosion control matting and grass seed by the Park's Biology

Technician and Student Conservation Assistant.

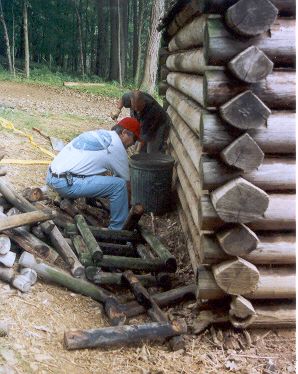

The next steps were to work on the huts themselves. Black Locust

trees were cut for the base logs, and large diameter oak logs for making

shingles were bought from a local sawmill and given by Lewis Morris County

Park. Supply of oak, walnut, locust, and sassafrass that is

clear and straight continues to be a problem, but enough was found to get

started.

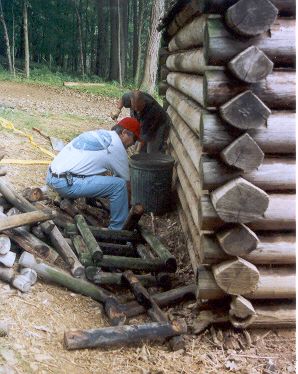

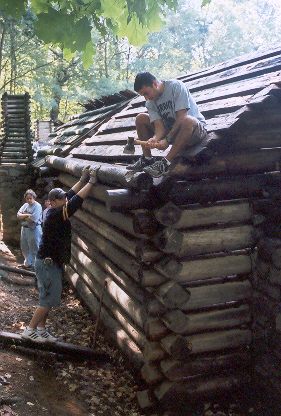

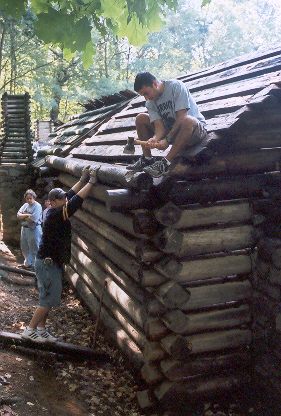

The first hut was lifted using mechanical jacks, and

four decayed logs were removed. Two logs that had slight rot to the

ends were repaired in place (middle photo). Four new logs of black locust

were cut and fit to each other and the logs above on the back and chimney

sides.

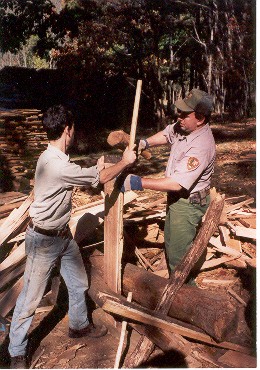

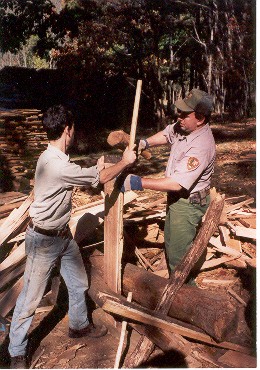

Roofing material was the next challenge. All of the historical

evidence supported the architect's original decision (in 1964) to use 4

foot long split shingles of oak. In the end, cedar had been used.

Only one supplier was found that could meet our needs in either (Lost Creek

Industries, Oregon). While that search was underway, we started making

our own shingles of oak.

Although the reproduction 18th-century mauls and wedges

were not yet ready, sledge hammers & steel wedges along with wooden

'gluts' did the same job for us.

Once the billets were thin enough, they were then riven

into shingles. Right photo courtesy of Scott Shepherd

Before the first roof could be installed, the chinking mortar and chimney

lining had to be removed and replaced. As expected, the 'dechinking'

was hard, tedious work. Fortunately, the 2nd NJ Regiment stepped

in, and with a few others, did in one weekend what would have otherwise

been four weeks worth of work for the exhibit specialist if he had worked

alone.

Using a combination of tools the mortar & lathe was

chipped, pounded and pulled out from between the logs.

The one problematic chimney and fireplace was taken

down as well. See deconstruction story about on the Morristown

NHP News page.

As the Fall of 2002 approached, two roofs were removed and it looked

like the first new roof would finally go on. However, additional

rot was found in the upper logs that had to be stablized. Further,

once the volunteers learned what we understood to be the original roofing

system of 1779, they encouraged us to show it in the exhibit huts if at

all possible. This required logs to be extended, but using a combination

of woodcraft and modern conservation techniques, it proved possible and

we forged ahead with it.

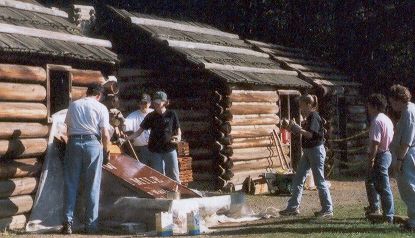

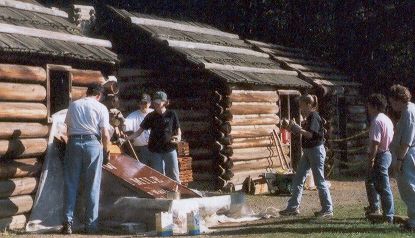

Prudential volunteers begin the process of coating the

cedar shingles for the first hut with a water repellent. (The oak

shingles will go on the next hut). They also helped install the new

roof pole and first row of shingles very much in the same manner the soldiers

at Morristown did in 1779-80..

|  |

Site Content:

Project Goals & Objectives (intro)

Overview of Initial Work (page 1)

Advancing into the Past (page 2)

Tools of the Trade (page 3)

Participating at the Pennsylvania Line (page 4)

Contact: Mathew Grubel

Morristown National Historical Park (973) 539-2016

Note: The project is on indefinate hold as of Dec. 2003

You are still welcome to contact me via direct e-mail

here.

Revision Date: 7/19/2004