1985 AMC Jeep Grand Wagoneer

Carburetor Vent Solenoid Rebuild

The Motorcraft

2150 carburetor on the AMC 360 has three fuel bowl vents. Two

vertical vents into the aircleaner housing and an external vent

to collect vapor when the engine is not running. A solenoid

activated valve keeps the external vent line shut when the engine is

running. Well, it is supposed to, but often when examined the tip

of the valve stem is missing. Where did it go? Your

carburetor bowl. :( Why?

Probably extended exposure to heat and compenents of gasoline,

especially today's reformulated fuels eventually caused the rubber(?)

to disintegrate. Unfortunately, this part, like the vapor

canister, is not readily available new. So, its repair time.

This is NOT a quick or easy repair. Hopefuly this write-up

will make it a little easier and let you hunt for tools and materials

before you start in.

>Also recomended is How-to: Rebuild your fuel bowl vent solenoid by "iroc86" on the IFSJA forum.

1. Solenoid valve before dissassembly.

Test valve for operation by turning ignition to "run".

Engine does not need to be running. This will power the solenoid and

the plunger will extend. If the tip survives, then no air can go

through (will hold a vacuum). If the tip is gone, look inside to

see the metal plunger. Turn ignition off and the plunger is no

longer visible.

Note the orientation of the inlet and outlet to the solenoid itself.

|

. .

|

2. Open up crimp.

This is an excercise in patience and care. I found the best tools

I had handy for this operation were a very sharp and thin punch and

light hammer. After getting enough of the crimp open, the small

screw driver and channel-locks were also useful.

|

|

3. Inside of Valve.

Notice the charcoal bits along with other dirt that hadn't

yet made it to the carb bowl. Charcoal bits? Where's that

from? The Vapor Canister. You can read about rebuilding

that here.

The crimp itself does not do any sealing. There is a o-ring that

seals the actuator to the base. It can be seen more clearly

in the next photo.

|

|

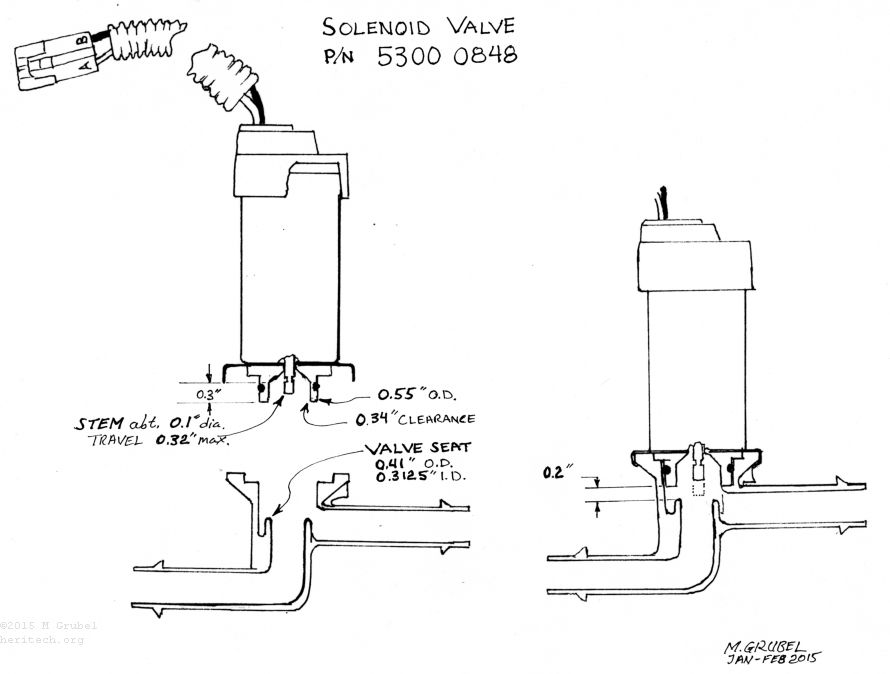

4. The valve seat has an i.d. of

5/16". Therefore the original tip either went into the seat

or was wider than 5/16". I tried two approaches, one

starting with hardwood dowel about 11/32" and the other with a nylon

"button". The button may have been a form of wall anchor for

picture hanging. You'll need to get creative here. What

you choose probably will depend on the materials and machinery you have

access to. A small lathe or milling maching opens up

possibilities. The drawing at the bottom of this page has measurements which should prove helpful.

The valve stem itself has a groove to help retain the tip. Again I believe a hard rubber was the original material.

|

|

5. Cleaned the valve with Goop. Not sure

what chems would be safe so I was conservative. Honestly, carb

cleaner would probably be OK on thehard white plastic ( nylon?).

Keep it away from the o-ring.

|

|

6. Slide the two parts together and orient as it was originally. Orientation is probably not super critical.

|

|

7. Test and recrimp. I used channel locks.

|

|

8. Added some self bonding tape to wrap it up.

|

|

|

|

|

|

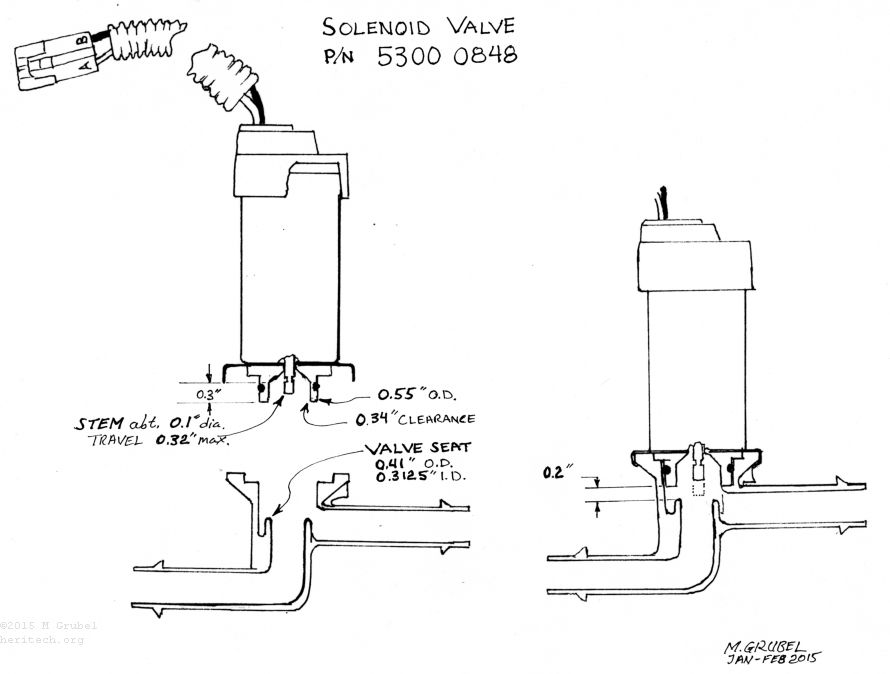

Cutaway Assembly Drawing of Solenoid Valve 5300 0848

Measurements were made with machinists scale and drill bit shanks. You should verify!

Disclaimer:

If you take advice, or copy something I have done,

you are on your own. I'm just trying to be helpful, but you need to

make your own decisions, and know about or discover the risks before barging

ahead on any endevour.

Claimer:

The information and pictures on this page are free

to use and share by all and may not be sold. If you steal

something I have written, or a picture

I have taken or drawn, you are a thief. Plain and simple.

If

you wish to quote something, you are free to do so. All I ask for

is proper credit.

rev. 3 Feb 3 Jan 2015

.

.